- A-

- A

- A+

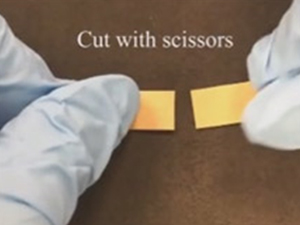

Electronic material self-heals and functions even after being cut in half

If you've ever bent a piece of wire or plastic back and forth until it broke, you understand one of the problems inherent in flexible electronics. The more circuits and connectors flex, the higher the likelihood they'll break, which can be a big problem for wearable electronics. While we've seen self-healing chips, gels and microcapsules before, a new material out of Pennsylvania State University (Penn State) brings auto-repair to dielectrics – the materials that insulate electric currents.

The material consists of plastic sheeting covered in boron nitride nanosheets. Boron nitride is a super-hard substance that's carbon-like in its structure. The sheets themselves are like graphene, but unlike that material, they resist – rather than conduct – electricity.

To get the nanosheet-covered plastic to have self-healing properties, scientists added hydrogen bonding groups to the surface of the nanosheets. They then demonstrated that they could go so far as to cut the material in half and still have it repair itself. That's because when the two halves of the severed material were brought close to each other, an electrostatic charge pulled them together, restoring the hydrogen bonds and "healing" the material.

Not only was the healed material then able to demonstrate its restored strength by supporting a 200 g weight (about 7 oz) just 30 minutes later, it was also able to show that all of its functionality had been healed including its electrical resistance, thermal conductivity and insulating properties. What's more, the material was able to restore its properties after multiple breaks.

Similar News

Links

Elm TV

Elm TV

Photo

Photo

Video

Video